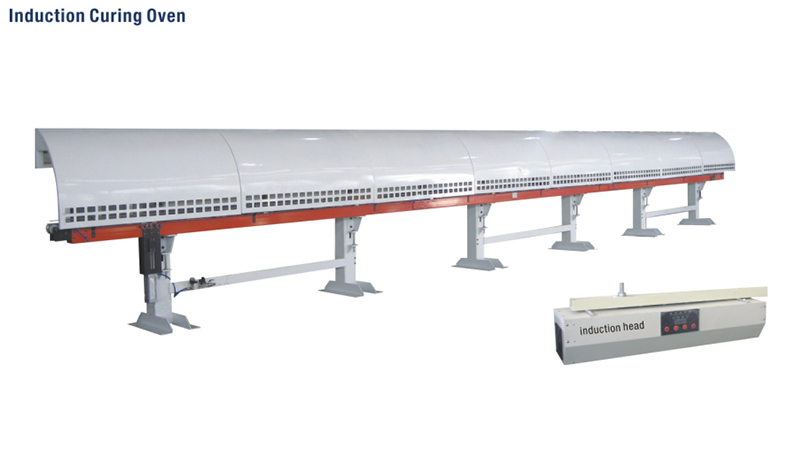

Induction Curing Oven

1. Every burner consumption is1.5-2kw/hour, take dia73mm/height 113mm can for example, 4 burners can dry 200cans/min can body line and 8 burners can dry 400cans/min can body line.

2. With multi grades adjustment design, pre-heating system for powder drying, save space and energy.

3. When can body welder jam and not continuous working due to some normal reasons, all the can bodies left on the transmission conveyor still can be dried by special induction system and no need ejection.

4. Every burner can dry 45 to 50cans per minute , depending on different Can diameter/height which will affect the induction area.

5. Use fan cooling system with very little electric power. Do not need cooling water which consume a lot of electric power and have the possibility of water leakage.

6. Down magnet belt transmission.

| Sales Model | INO120/150 | INO220 | INO300 | INO500 | INO600 |

| Can diameter | 52 to 153mm | 52 to 153mm | 52 to 153mm | 52 to 99mm | 52 to 99mm |

| Can height | 80-320mm | 80-320mm | 80-320mm | 80-320mm | 80-320 |

| Copper wire speed | 15m | 25m | 40m | 50m | 60m |

| Length of oven | 10m(straight line) | 14m(straight line) | 11m(U type) | 13m(U type) | 15m(U type) |

| Number of induction oven | 4 pcs | 6 pcs | 8 pcs | 10 pcs | 12 pcs |

| Power comsumption | 12KW/hour | 20KW/hour | 25KW/hour | 30KW/hour | 35KW/hour |